Lots of soap makers like to avoid palm oil when making soap. Sometimes it is difficult to find a recipe that works well because palm oil is such a good soap making oil.

However, we've made use of our soap making expertise and produced a great palm free cold process soap recipe.

Read on to find out more!

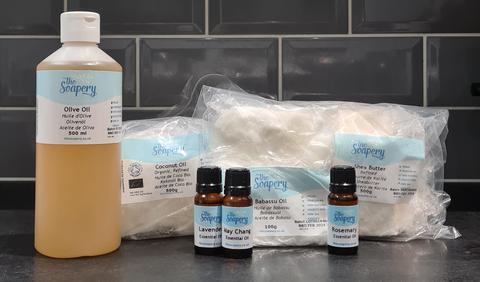

Ingredients:

- Olive oil 250g | 270ml

- Coconut oil 90g

- Babassu oil 80g

- Castor oil 30g | 31ml

- Water 140g

- Sodium hydroxide 70g

- Lavender essential oil 6g | 7ml

- May chang essential oil 3g | 3ml

- Rosemary essential oil 2g | 2ml

Equipment

- Gloves

- Goggles

- Weighing scales

- Hand blender

- A silicone soap mould or DIY alternative (Check out our range of soap moulds here)

- 3x plastic jugs. Ideally 1x 2L and 2x 1L

- Silicone spatula

- Digital thermometer

Safety Note: When working with sodium hydroxide you must wear gloves and goggles at all times. It is a caustic product and will burn. In the event of getting it on your skin, rinse well with plenty of plain water. If it is splashed in the eyes, wash with water and seek urgent medical attention. Keep away from pets and children at all times.

Makes 6-7 bars of soap

Takes 1 hour making time and 4-6 weeks curing time

This recipe uses a 5% superfat for extra moisture.

Method:

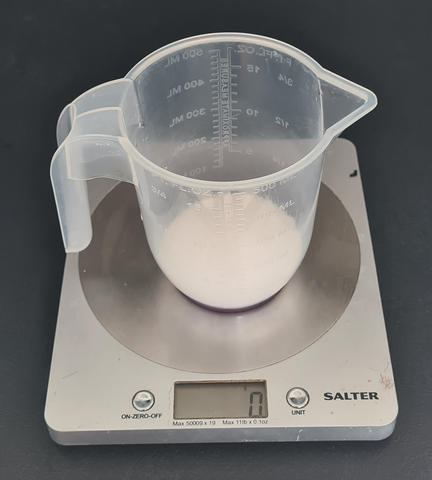

1. Make your sodium hydroxide solution

- Weigh your cold water into one of your jugs

- Put your gloves and googles on, and make sure you're working in a well ventilated area. Open a window!

- In another jug weigh you sodium hydroxide

- Add your sodium hydroxide to your water, not the other way around!

- Stir for around 10-15 seconds until the sodium hydroxide is dissolved in the water.

- Leave it to cool

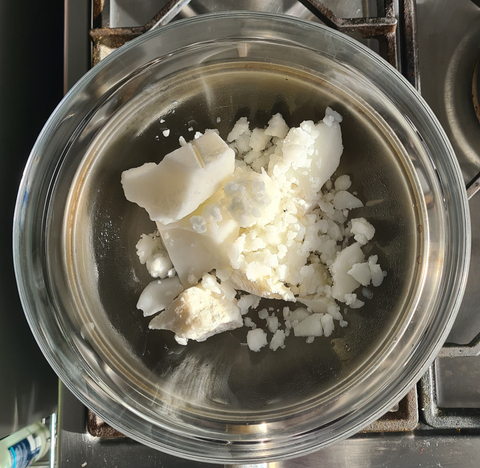

2. Measure and heat your oils

- In a jug or heatproof bowl, measure your solid oils

- Weigh and combine your olive oil and castor oil

- Add your liquid oils to the solid oils

- Heat in a pan over boiling water, or using short bursts in the microwave

- Mix well and heat until melted

- Weigh out your essential oils into a separate jug

3. Check the temperature of the mixtures

- Check the temperature of your sodium hydroxide solution. You're looking for between 25 and 40C. Don't heat it up if it is too cool though, just heat your oils a little more to compensate.

- Test the oil temperature, they need to be between 35C and 40C. You can reheat them if necessary.

- Add your essential oils to your oil mixture.

- Pour the sodium hydroxide solution into the oil mixture.

- Make sure your moulds are close at hand, you'll need them in a moment.

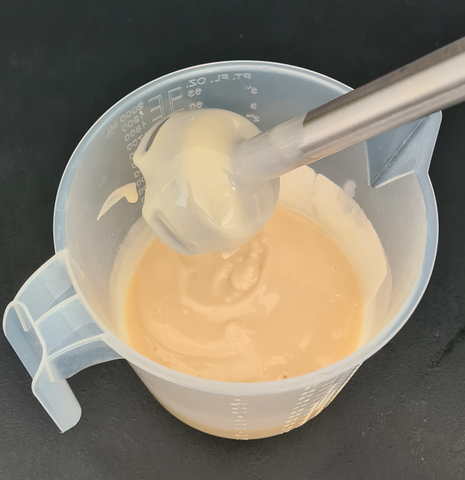

4. Blend until trace

- Stir gently with the hand blender until the mixtures are combined

- Pulse the blender for a few seconds at a time, keeping an eye on how the mixture starts to thicken.

- Stop blending when your soap has reached trace. This is when you drip some soap batter across the jug of mixture and it sits on top for a moment. The picture above is a medium to heavy trace.

5. Pour into moulds

- Pour your soap into moulds.

- Gently tap the mould to get rid of air bubbles and to help the soap set evenly.

- Place the soap on a flat surface and leave it for 48 hours before unmoulding.

6. Unmould and cure your soap

- Remove your soap from its mould

- Place the bars with spaces in between and leave them to cure for 4 - 6 weeks.

How did your soap look? Take a look at more of our cold process soap recipes